Product Description

RF-8002 is used in waterproof finishing for chemical fiber fabrics. In addition, RF-8002 is water-proof, oil repellent, antifouling.

It has good environmental stability and is especially suitable for waterproof finishing of polyester fabrics.

Features and Benefits

Typical Properties1)

|

Property |

Typical Values |

|

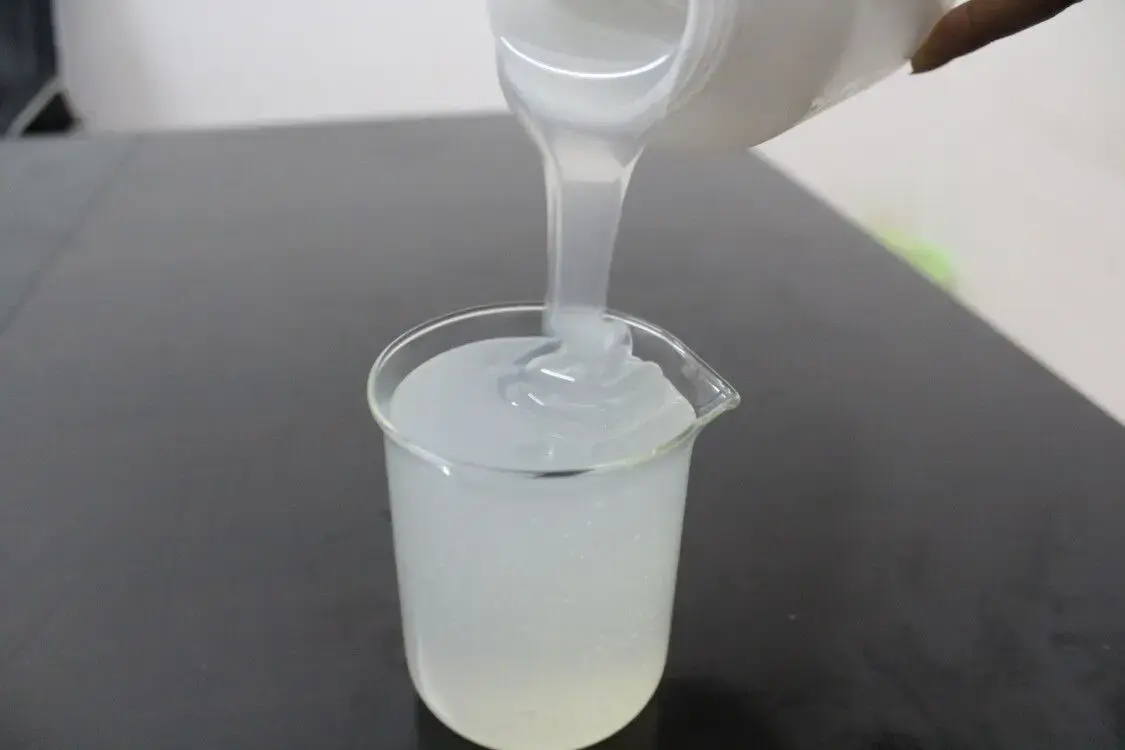

Appearance |

Milky white |

|

Solid content, wt% |

30.0 ± 1 |

|

pH |

3.0-5.0 |

|

Ionicity |

Weak cation |

1)Please note that the values shown are typical values for your guidance. They are not to be taken as specifications and are subject to certain variability. Please consult the sales specifications for details.

Formulating Guidelines

Fabric process

Before waterproof and oil-proof finishing of fabrics, the oil, alkali, softener and anionic surfactant left in the washing process must be fully removed, and then washed with clean water.

Applied Technology

It is suitable for general waterproof processing of synthetic fibers (polyester, nylon) and other fabrics.

Recommend usage: 10-50g/L, dipping coating, drying, and setting. Users are requested to adjust the specific process through the sam- ple as appropriate.

Health and Safety Considerations

Safety Data Sheets (SDS) are available from Zhejiang Ruico Ad- vanced Materials Co., Ltd. are provided to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.

SDS is updated regularly, therefore, please request and review the most current SDS before handling or using any product. For further questions consult your Ruico contact person.

Packaging and Storage

RF-8002 should be stored in dark and cool place, at temperatures between 5°C and 30°C in tightly sealed containers, valid for 3 months. Avoid freezing of the material! Local legislation on stor- age must be followed.

RF-8002 is protected against microbial attack during transporta- tion and storage in not opened original packaging. There are two types of packaging: 50kg plastic drums, 160kg plastic drums.

To avoid problems with the microbial attack during processing and in opened packaging attention should be paid to hygiene. In some cases, it could make sense to add biocides to avoid prob- lems with microorganisms.

We recommend using the product under safety precautions as described in the SDS. Avoid contact with eyes and skin. Large quantities should be handled in a correctly ventilated area. The material can create slippery conditions.

Customer Notice

Ruico does not warrant or guarantee the effectiveness of our prod- ucts added to any textile fibre or fabric. Before putting into mass production, multiple trials and tests must be done in accordance with your company’s production technology, in order to obtain corresponding certified effect.

RF-8002 water-proof oil repellent antifouling agent

Ruico strongly encourages its customers to review both their manufacturing processes and their applications of Ruico products from the standpoint of human health and environmental quality to ensure that Ruico products are not used in ways for which they are not intended or tested.

Ruico personnel are available to answer your questions and to provide reasonable technical support. Ruico product literature, including safety data sheets, should be consulted prior to use of Ruico products. Current safety data sheets are available from Ruico.

Product Description

RF-8004 is the polyhydroxy compound. It can increase the form- ability and stiffness of acrylic emulsion and polyurethane emul- sion.

The product is stable at the room temperature and when it is used in the high temperature (80-100 degrees), it will crosslink. If dry and heat treated, the product will give full play to its excellence.

Features and Benefits

Typical Properties1)

|

Property |

Typical Values |

|

Solid Content, % |

10 ± 2 |

|

pH |

2.0 - 5.0 |

|

Viscosity (Brookfield LV, spindle 2 |

<1,000 cps |

|

Appearance |

Transparent viscous |

|

Solubility |

Easy to soluble in water |

1)Please note that the values shown are typical values for your guidance. They are not to be taken as specifications and are subject to certain variability. Please consult the sales specifications for details.

Safety Data Sheets (SDS) are available from Zhejiang Ruico Ad- vanced Materials Co., LTD. SDS are provided to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety reg- ulations. SDS are updated regularly, therefore, please request and review the most current SDS before handling or using any prod- uct. For further questions consult your Ruico contact person.

Packaging and Storage

RF-8004 should be stored in dark and cool place, at temperatures between 5°C and 30°C in tightly sealed containers, valid for 6 months. Avoid freezing of the material! Local legislation on stor- age must be followed.

RF-8004 is protected against microbial attack during transporta- tion and storage in not opened original packaging. There are two types of packaging: 50kg plastic drums, 160kg plastic drums.

To avoid problems with microbial attack during processing and in opened packaging attention should be paid on hygiene. In some cases it could make sense to add biocides to avoid problems with microorganisms.

We recommend using the product under safety precautions as described in the SDS. Avoid contact with eyes and skin. Large quantities should be handled in a correctly ventilated area. Materi- al can create slippery conditions.

Customer Notice

Ruico does not warrant or guarantee the effectiveness of our prod- ucts added to any textile fibre or fabric. Before putting into mass production, multiple trials and tests must be done in accordance with your company’s production technology, in order to obtain corresponding certified standard. Mix well before use.

Ruico strongly encourages its customers to review both their manufacturing processes and their applications of Ruico products from the standpoint of human health and environmental quality to ensure that Ruico products are not used in ways for which they are not intended or tested.

Ruico personnel are available to answer your questions and to provide reasonable technical support. Ruico product literature, including safety data sheets, should be consulted prior to use of Ruico products. Current safety data sheets are available from Ruico.

RF-8502 Thickener

Rheology Modifier

RF-8502 is a crosslinked macromolecule emulsion thickener, co- polymerized by acrylate and methacrylate.

It has acidic groups, high molecular weight, and high thickening efficiency.

It also has excellent anti-sedimentation, mold resistant and mil- dew resistant, resulting in long-term viscosity stability.

RF-8502 is easy to use, suitable to be used as the thickener in in- terior and exterior wall latex paints, emulsion paint, textile coat- ings, textile printing, pigment printing, pressure sensitive adhe- sives emulsion, and so on.

Features and Benefits

Typical Properties1)

|

Property |

Typical Values |

|

Solid content, wt% |

30.0 ± 1 |

|

pH |

2.0-4.0 |

|

Viscosity (Brookfield LV, spindle 1 |

<100cps |

|

Ionicity |

Anionic |

1)Please note that the values shown are typical values for your guidance. They are not to be taken as specifications and are subject to certain variability. Please consult the sales specifications for details.

Formulating Guidelines

Use ammonia to adjust the pH of the paint to 8-9. It is recom- manded to slowly add RF-8502 diluted 1:2 with water, under low speed stirring. Observing the changes in the viscosity of the paint while stirring. After reaching the desired viscosity, stop adding the thickener.

Safety Data Sheets (SDS) are available from Zhejiang Ruico Ad- vanced Materials Co., Ltd. are provided to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.

SDS is updated regularly, therefore, please request and review the most current SDS before handling or using any product. For further questions consult your Ruico contact person.

Packaging and Storage

RF-8502 Thickener should be stored in dark and cool place, at temperatures between 5°C and 30°C in tightly sealed containers, valid for 6 months. Avoid freezing of the material! Local legisla- tion on storage must be followed.

RF-8502 Thickener is protected against microbial attack during transportation and storage in not opened original packaging.

There are two types of packaging: 50kg plastic drums, 160kg plastic drums.

To avoid problems with the microbial attack during processing and in opened packaging attention should be paid to hygiene. In some cases, it could make sense to add biocides to avoid prob- lems with microorganisms.

We recommend using the product under safety precautions as described in the SDS. Avoid contact with eyes and skin. Large quantities should be handled in a correctly ventilated area. The material can create slippery conditions.

Customer Notice

Ruico does not warrant or guarantee the effectiveness of our prod- ucts added to any textile fibre or fabric. Before putting into mass production, multiple trials and tests must be done in accordance with your company’s production technology, in order to obtain corresponding certified effect.

Ruico strongly encourages its customers to review both their manufacturing processes and their applications of Ruico products from the standpoint of human health and environmental quality to ensure that Ruico products are not used in ways for which they are not intended or tested.

Ruico personnel are available to answer your questions and to provide reasonable technical support. Ruico product literature, including safety data sheets, should be consulted prior to use of Ruico products. Current safety data sheets are available from Ruico.