Update:

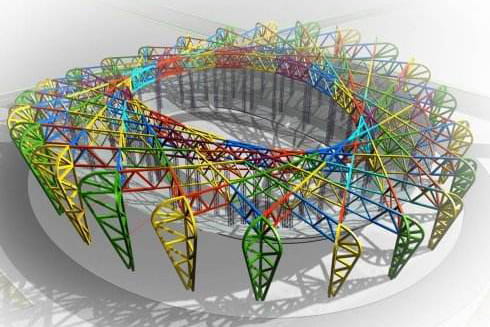

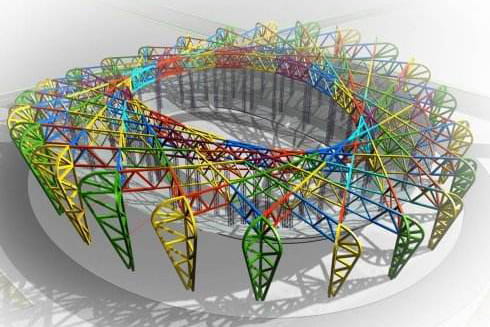

As the main form of modern buildings, steel structure has the advantages of light weight, high strength, good seismic...

As the main form of modern buildings, steel structure has the advantages of light weight, high strength, good seismic performance, short construction period, high degree of industrialization of buildings, and large space utilization at room temperature. It is widely used by investors to save investment for enterprises. However, the poor fire resistance of steel structure buildings is also very obvious, because although steel is a non-combustible material, it is a good conductor of heat and easily conducts heat. After the temperature of the steel exceeds 300 degrees, the yield point and ultimate strength decrease significantly, and the strength is almost zero when it reaches 600 degrees. In the event of a fire, the unprotected steel structure will only take 15 minutes to increase its temperature to more than 540 degrees, causing the component itself to be distorted and deformed, causing the building to collapse and destroy, and the deformed steel structure cannot be repaired and used. Therefore, fire protection measures must be taken for steel structures, and fire-resistant coatings or flame retardants must be applied

Preparation before construction:

According to the requirements of the construction plan for steel structure fireproof coatings, the surface of the substrate should be derusted and anti-rust treated as required before the construction of the fireproof coating, so as to be thorough. Before the construction of the fireproof coating, dust, oil and other impurities should be removed from the substrate surface. High-pressure gas or high-pressure water guns are used for surface dust removal and cleaning, and fireproof coatings can be applied only after the surface of the substrate has no water for dust removal, debris removal, and oil stains.

- Treatment of the surface to be coated: Before construction, the surface of the supporting member should be cleaned (including rust removal, welding slag and other dirt); check whether there is any leakage of the anti-rust primer on the surface of the steel structure, and repair it in time .

- Storage of fireproof paint: The paint that has passed the inspection should be stored in a dry and ventilated warehouse. The paint should be placed neatly to prevent wind, rain, and sun exposure. Paint that has become agglomerated and deteriorated should not be used.

Construction of fireproof coating:

- Use spraying method.

- Coating construction: The steel structure fireproof coating should be fully stirred before construction and use. After the first construction, the second construction should be carried out 18-24h after the surface is dry. The subsequent construction should be carried out. The thickness of the coating should be according to requirements Control until the specified thickness is reached. The construction time interval is more than 18-24 hours, and the construction environment temperature is 0-40℃. The substrate temperature is 5-45°C. The relative humidity of the air is not more than 90%, the construction site has air circulation, and the wind speed is not more than 5m/S. It is not suitable for outdoor operation or when the surface of construction components is dew.

- Spraying of fireproof coating: spraying the bottom material, in order to improve the bonding strength between the coating and the steel beam base layer, a small amount of water-based adhesive should be added to the bottom slurry. There are obvious papillae and pits on the coating surface, which should be smoothed with a spatula. Before spraying, test spray and make a sample. The optimum parameters of the process, such as spraying air pressure, spray distance, spray gun moving speed, etc., are determined through test spraying, and then large-area spraying can be carried out after the supervisor has compared and confirmed with the standard model. When spraying, the spray gun should be perpendicular to the surface of the steel component to be sprayed, and the spray distance should be 6-10 mm and maintained at 0.4-0.6MP. The running speed of the spray gun should be stable and not stay in the same position for a long time to avoid the accumulation and flow of paint. During the spraying process, the batching and feeding of the spraying machine must be carried out continuously, without stopping. After the surface of the primer is dry (24 hours after the primer is applied), spray the surface coating. For obvious unevenness, use a spatula to smooth the surface to ensure a uniform and clean coating surface.

Matters needing attention during construction:

- The fireproof paint should be rainproof and moistureproof during transportation and storage.

- Fire-resistant paint shall not be used when it is cured or agglomerated. The coating that has just been applied should be protected from rain.

- If the paint thickens during use (it does not take too long to harden), add a small amount of water and stir evenly before using.

- After the paint is sprayed, it is advisable to cover it with plastic cloth or other objects to prevent direct strong wind and direct sunlight from causing the coating to crack.

- The parts that do not need to be sprayed should be covered before spraying. Once pollution is caused, they should be cleaned immediately.

- After spraying tools are stopped, they should be cleaned immediately for reuse.

- Construction temperature: during construction and within 24 after construction, the surrounding environment of construction and the temperature of steel components should be kept above 5℃. If this temperature condition cannot be met, other special measures should be taken to prevent the coating from freezing. When the wind speed is greater than 5m/s, or there is condensation on the surface of the component in rainy weather, it is not suitable to work.

- The initial strength of fireproof coating is low and it is easy to be damaged. Therefore, spraying should be carried out after the construction of the relevant steel structure to prevent strong vibration and collision.

- If there is an upper and lower grade crossing operation during construction, pay attention to safety. Especially the operators on the scaffold should be more careful. The operators must wear protective equipment and fasten the safety belt before they can operate.

Ruico experts in Flame retardant materials, provide high quality product to help clients to protect steel structure when fire.

Regional Sales Manager

Zhejiang Ruico Advanced Materials Co., Ltd. (Stock No.873233)

Add: No.188, Liangshan Road, Linghu Town, Nanxun District, Huzhou City, Zhejiang Province, China 313018

Phone: +86 (572) 2903236

Fax: +86 (572) 2905222

WhatsApp: +86 15968208672

Cellphone: +86 15968208672

Website:www.ruicoglobal.com

E-mail: [email protected]